Patrick Collins

Postdoc, Diamond Light Source

Before Patrick Collins was introduced to the Echo® 550 Liquid Handler, he and his colleagues often found themselves in a cold room armed with a scalpel and pipette, cutting holes in the film covering 96-well crystallization plates, adding compounds, recording the transfer details on scraps of paper, then repeating. Over. And over. And over. It was a long and tedious process, to say the least.

So when he entered the lab of Frank von Delft, a Principal Beamline Scientist at Diamond Light Source in Oxfordshire, the United Kingdom's national synchrotron science facility, he was thrilled to learn that the lab had acquired an Echo system which promised to transform the crystal soaking experiment.

“It’s fantastically fast – orders of magnitude faster,” Collins says. “It can soak 1,000 crystals in 10 minutes. That’s a three-month job the old way.”

The Echo system has transformed not only the workflow in one beamline lab, but entirely how macromolecular crystallography can be used for compound discovery, in particular for fragment screening.

When Dr. Collins joined Diamond as a postdoc in 2014, he was tasked with figuring out a way to automate crystal soaking at the facility, which provides services for both academia and industry. Bringing together specialists from across the company, he and the team created protocols and pipelines, work-arounds and workflows.

XChem, a first-of-its-kind, highly streamlined fragment screening lab that made it possible for individual scientists to finally take advantage of the powerful X-ray crystallography approach to early drug ("lead") discovery. The process covers soaking, harvesting, automatic data collection, and data analysis; fragment libraries are available, though users can also bring their own.

What started with a handful of users by 2016, has become a fully established user programme that has already hosted over 75 experiments from both academia and industry. The number of crystals processed has correspondingly jumped, from a few thousand in 2015 to 35,000 in 2017: each experiment entails 500–1000 individual diffraction datasets prepared and measured in under a week. The program has grown so much that the lab has moved into a larger space and purchased a second Echo system, allowing multiple users to set up their experiments simultaneously.

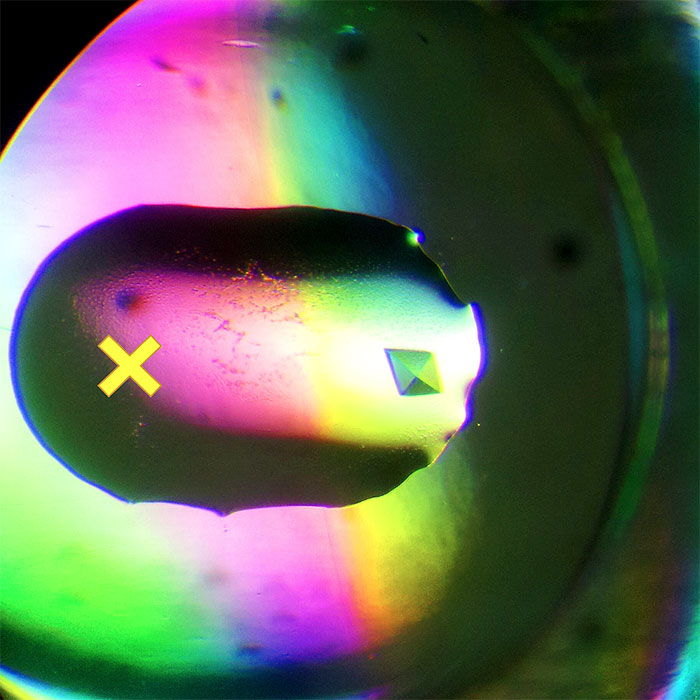

Crystal-based fragment screening is an extreme application of crystal soaking, the process of taking pre-grown crystals and soaking them with the small molecule of interest. The potential ligand can access the binding sites by diffusing through solvent channels within the crystal lattice. However, the low solubility of many compounds in aqueous solutions often requires the use of organic solvents such as dimethylsulfoxide (DMSO) for solubilization. This can alter the chemistry of the crystal drop and affect the integrity of the crystal.

Therefore, Diamond’s automated system not only needed to be rapid and robust to allow high throughput, it required the method to be gentle, so that compounds can be added to crystals without destroying them. Acoustic liquid droplet ejection via the Echo system provided a great solution for all of those goals.

Thanks to the positional precision of acoustic droplet ejection, XChem users are able to target the placement of the compound/solvent away from crystals and towards drop edges, allowing gradual diffusion of solvent across the drop.

"This ensures both an improvement in the reproducibility of X-ray diffraction and increased solvent tolerance of the crystals, thus enabling higher effective compound-soaking concentrations,” Dr. Collins says. “The crystals are much more consistent, and we get more consistent results.”

Collins detailed the technique in this paper in Acta Crystallographica, with examples from the protein target JMJD2D, a histone lysine demethylase with roles in cancer and the focus of active structure-based drug-design efforts.

“The precision and volume scales of acoustic transfer have enabled new developments in protein crystallography,” Collins writes. “The ability of the Echo system to dispense solvent to arbitrarily requested locations within a subwell, or to dispense with a complex pattern in 2.5 nL units, opens up possibilities for crystal-soaking experiments that are not possible to perform by hand.”