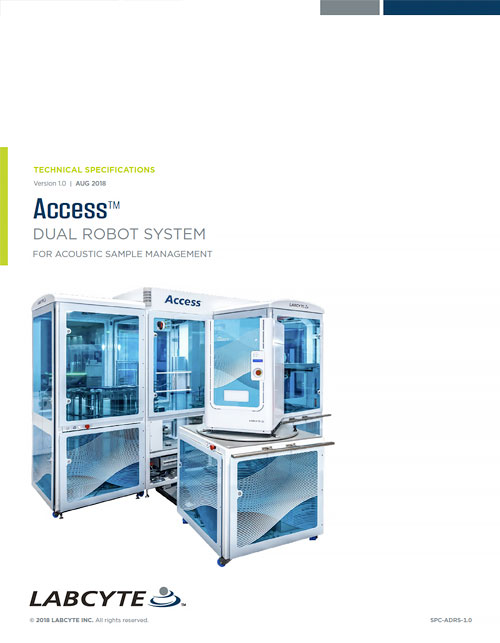

Access SINGLE and DUAL ROBOT SYSTEMS

- Modular

- Configurable

- High-capacity

- High-throughput

- Environmental distribution option

Superior Automation for Acoustic Liquid Handling Workflows

Access Single (SRS) and Dual Robot Systems (DRS) are compact, modular, high-throughput platforms, that are designed and optimized for the use of Echo Liquid Handlers. They are the only automation platforms compatible with the new Echo 650T and 655T Liquid Handlers, enabling all acoustic workflows including the automation of acoustic sample tubes. These systems combine industry-leading devices and software with ergonomic and environment management options to provide a complete, easy-to-use, automation solution.

Key Benefits

- Maximum throughput and uptime for Echo Liquid Handler integrations

- Superior flexibility in a compact footprint

- Ergonomically designed and certified for laboratory use

- Minimized sample hydration with environmental management option

- Includes Tempo 2 Software with advanced features for large-scale applications

Access Dual Robot System for Acoustic Sample Management

This video of an Access DRS designed specifically for acoustic sample management demonstrates high-throughput, assay-ready plate production. The automation platform combines new acoustic tube and acoustic liquid handling technologies, along with industry leading devices, to provide an unmatched level of throughput and quality. It is the only automated system that can acoustically process nanoliter volumes directly from tubes to microplates, enabling higher throughput, less sample usage, and optimized sample integrity.

FluidX AcousticX Sample Tube by Brooks Life Sciences

The FluidX AcousticX Sample Tube (FAST) transforms sample management workflows by enabling acoustic dispensing directly from tubes. The meticulous tube design features a revolutionary cap to increase automated capping cycles from 15 to over 500 cycles, a DMSO resistant gasket to reduce hydration and evaporation, and replicate 2D barcodes that provide a clear path for acoustic energy to pass through to the sample.

- Maximum throughput and uptime for Echo Liquid Handler integrations

- Superior flexibility in a compact footprint

- Ergonomically designed and certified for laboratory use

FluidX AcousticX Sample Tube an Echo Qualified Consumable

| Echo models | 655T and 650T |

| Working volume | 15 - 70 µL* |

| Dead volume (Echo) | < 15 µL |

*Working volume is dependent on acoustic liquid handling technology and fluid type

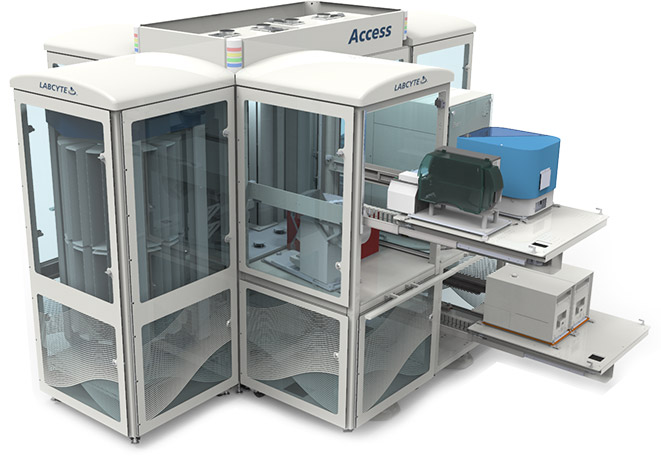

Modular

Configure and reconfigure system modules to meet application needs. Dock and undock up to 6 standardized modules for integrating echo systems, plate handling devices, and plate handling stores.

SRS

DRS

Access to Devices

Easily access devices for standalone operation or maintanance for configuring system modules with retractable shelves, turntables, and automated docking systems. The automated push button docking system allows operators to temporarily undock modules without stopping runs that are in progress.

Integrated Environmental Control

Access SRS and DRS systems can be configured with environment options that include a direct integration with Lab HVAC systems to supply controlled air and/or draw out air, or HEPA filter fans to supply a positive pressure, particulate-free environment.