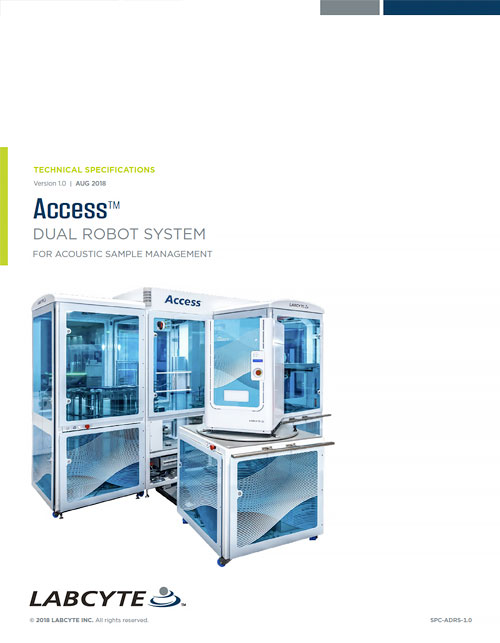

Access DUAL ROBOT SYSTEM

for Acoustic Sample Management

- Modular

- Configurable

- High-capacity

- High-throughput

- Environmental distribution option

The New Sound of Sample Management

The Access Dual Robot System (DRS) is a compact, modular, high-capacity, and high-throughput platform, designed and optimized for the use of Echo Liquid Handlers in sample management workflows. It is the only automation platform on the market compatible with the Echo 655T Liquid Handler, enabling the production of assay-ready plates from acoustic sample tubes. The system combines industry-leading devices and software with ergonomic and environment management options to provide a complete, easy-to-use, store-to-assay sample management solution.

Key Benefits

- Maximum throughput and uptime for Echo Liquid Handler integrations

- Superior flexibility in a compact footprint

- Ergonomically designed and certified for laboratory use

- Minimized sample hydration with environmental management option

- Includes TEMPO 2.0 Software with advanced features for large-scale applications

Access Dual Robot System for Acoustic Sample Management

This is a workflow video of the Access Dual Robot System (DRS) by Labcyte. The Access DRS is a compact, modular, high-capacity, high-throughput platform, designed and optimized for the use of Echo Liquid Handlers in sample management workflows. It is the only automation platform on the market compatible with the Echo 655T Liquid Handler, enabling the production of assay-ready plates from acoustic sample tubes. The system combines industry-leading devices and software with ergonomic and environment management options to provide a complete, easy-to-use, store-to-assay sample management solution.

FluidX AcousticX Sample Tube by Brooks Life Sciences

The FluidX AcousticX Sample Tube (FAST) transforms sample management workflows by enabling acoustic dispensing directly from tubes. The meticulous tube design features a revolutionary cap to increase automated capping cycles from 15 to over 500 cycles, a DMSO resistant gasket to reduce hydration and evaporation, and replicate 2D barcodes that provide a clear path for acoustic energy to pass through to the sample.

- Maximum throughput and uptime for Echo Liquid Handler integrations

- Superior flexibility in a compact footprint

- Ergonomically designed and certified for laboratory use

FluidX AcousticX Sample Tube an Echo Qualified Consumable

| Echo models | 655T and 650T |

| Working volume | 15 - 70 µL* |

| Dead volume (Echo) | < 15 µL |

*Working volume is dependent on acoustic liquid handling technology and fluid type

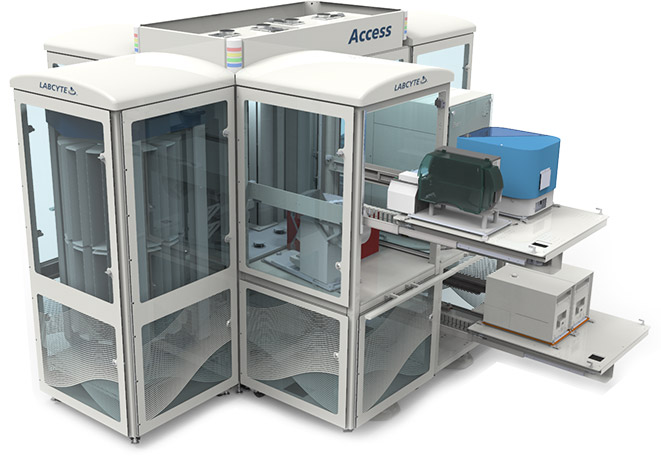

Modular

Configure and reconfigure system modules to meet application needs. Dock and undock up to 6 standardized modules for integrating echo systems, plate handling devices and plate handling stores.

Access to Devices

Easily access devices for standalone operation or maintanance for configuring system modules with retractable shelves, turntables, amd automated docking systems. The automated push button docking system allows operators to temporarily undock modules without stopping runs that are in progress.

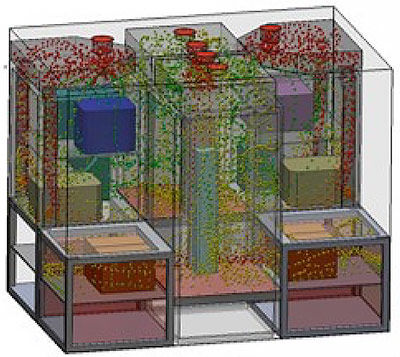

Preserve Sample Quality

An integrated environment distribution system avoids DMSO hydration, maintains sample integrity, and ensures downstream data quality. The system evenly distributes and recirculates conditioned air from laboratory HVAC system to each module of the platform, providing a dry, ambient internal environment.

TEMPO 2.0 Automation Control Software

With TEMPO 2.0 Software, Access DRS operators can easily coordinate plate handling tasks, manage consumable inventories, and report information in real time to LIMS or databases. Like previous versions, TEMPO 2.0 Software remains the only automation software that readily imports protocols from Echo Software Applications, simplifying protocol setup and schedule optimazation.

TEMPO 2.0 software includes new features to promote usability, throughput and uptime.

- Multi-robot coordination

- Module and device presence detection

- Run throughput optimization

- Improved integration with LIMS

- Device and consumable utilization tracking

- Advanced error recovery

- Simultaneous run processing and prioritization

- More methods for plate labeling

- Integration with external labaratory or building management systems

- Inventory search capabilities

Mosaic TFM by Titian Software

The Mosaic Tempo Fullfilment Module (MTFM) from Titian Software combines the scheduling power of TEMPO 2.0 Software with the inventory management expertise of Mosaic sample management software. This new model for Mosaic software captures the exact transfer and survey volumes as well as sample concentrations reported by Echo Liquid Handlers. Combined with sample lifecycle information, Mosaic software can better track sample distribution, freeze thaw cycles, and tube decap/cap operations to monitor sample integrity and utilization.

- 1Create order using Mosaic software

- 2Retrieve samples from storage

- 3Process order on Access DRS

- 4Report sample and process information